Home » Charge Air

Portfolio

Charge Air

Veritas air flow systems use the dynamics of air for turbocharging very efficiently. When designing lines for charge air, we always keep an eye on the requirements for pressure, temperature and noise behavior as well as chemical resistance. Our proven system- and materials expertise goes hand in hand with the competence for processes with the greatest possible real net output ratio.

Requirements-optimized specific product solutions by Veritas:

- Clean air intake

- Charge air system (air and water cooling)

- Negative pressure control line

- Exhaust gas recirculation

- Air supply line

Product features and special characteristics:

- Best properties through specific polymers respectively compounds, which are developed, validated and manufactured by Veritas.

- Reliable and proven connection systems

- High real net output ratio through in-house production of essential materials and components.

- System design including own mold flow and CFD analysis (flow dynamics).

- In-house injection molding and blow molding processes.

- Comprehensive test facilities and test procedures for validating all assemblies and the overall system.

High temperatures Extreme chemical resistance (ph1.0) High degree of freedom ridge in terms of gradient design options

Place: Engine compartment Charge air duct

Materials: FKM elastomer injection molding

Function: Connection hose for low pressure exhaust gas recirculation EGR cooler for charge air intake

High temperatures Extreme chemical resistance (ph1.0) Weight optimized

Place: Engine compartment Charge air duct

Materials: Hose with balance shaft (Bellow): F-TPV / HT-ACM | Flange connection: Plastic injection molding PPS GF40

Function: Connection hose for low pressure exhaust gas recirculation EGR cooler for charge air intake

High temperatures Extreme chemical resistance (ph1.0) High degree of freedom ridge in terms of gradient design options

Place: Engine compartment Charge air duct

Werkstoffe: FKM Elastomer Spritzguss

Funktion: Verbindungsschlauch für Niederdruck Abgasrückführung AGR-Kühler zur Ladeluftansaugung

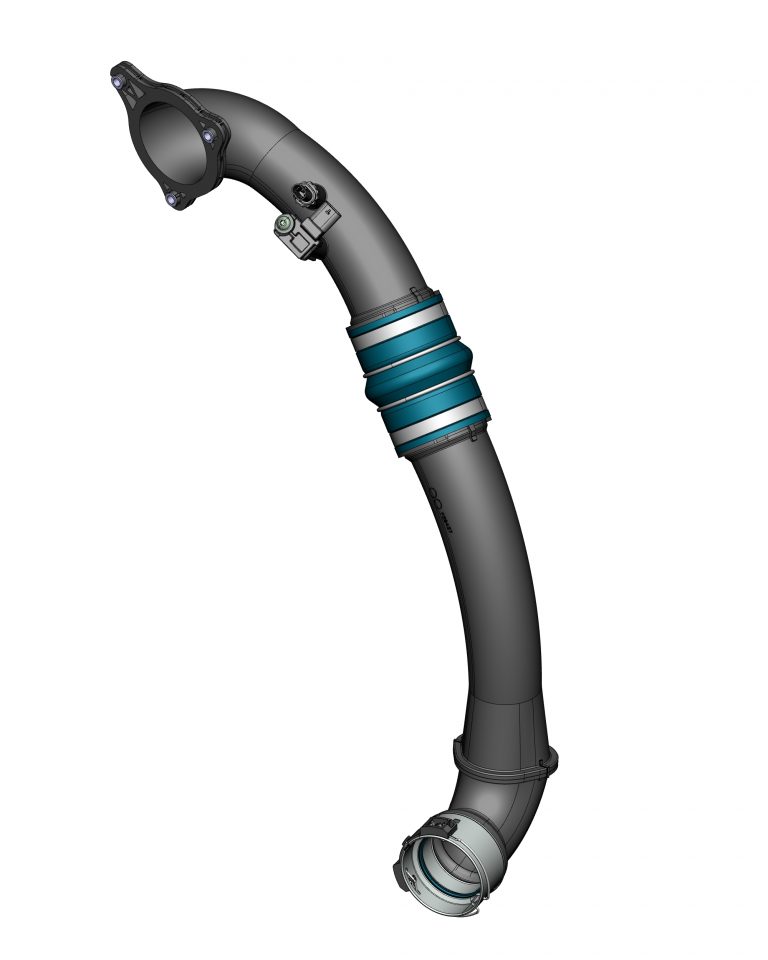

Place: Engine compartment Charge air duct

Materials: Injection-molded pipes welded in one or more parts PA66.6 GF30 Hose HT-ACM / DT / HT-ACM with balance shaft

Air duct on the pressure side from the turbocharger to the engine throttle valve

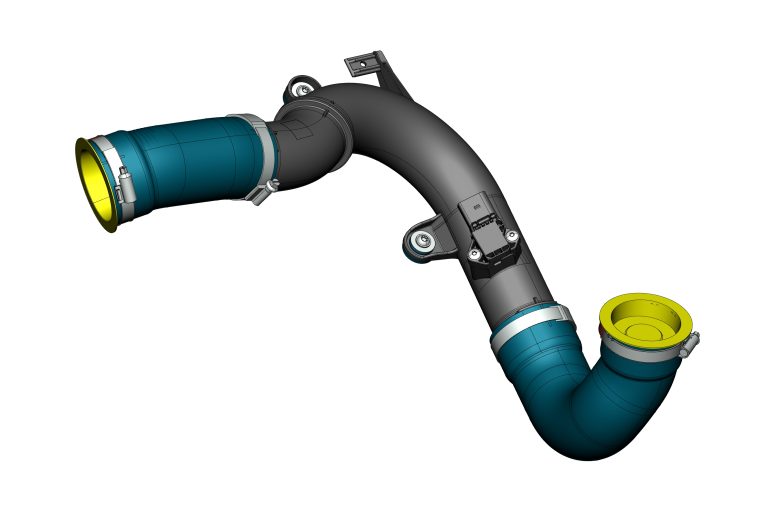

Place: Engine compartment Charge air duct

Materials: Injection-molded pipes welded in one or more parts PA66.6 GF30 or as a blow molding pipe Hose AEM / DT / AEM

Air duct on the pressure side from the turbocharger to the radiator or from the radiator to the throttle valve